The Mid-Scale Type B Containment Solution

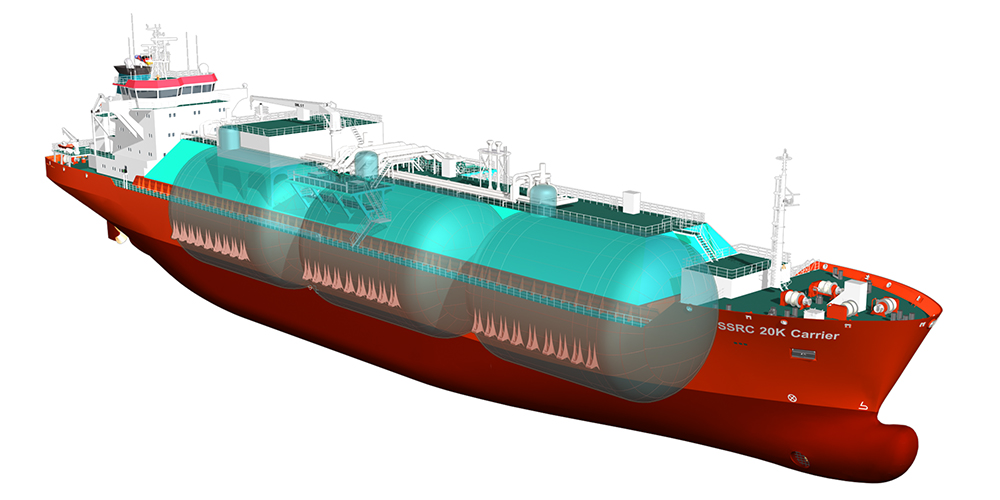

The SSRC Type B patented containment technology is conceived to address the needs of the mid-scale liquefied gas markets. It provides excellent thermal performance, low weight and ease of fabrication. In cooperation with world-renown Moss Maritime AS, SSRC Technologies introduces a novel Type B containment system specifically designed for the mid-scale LPG, NH3, Petchem and LNG markets. The SSRC system is also uniquely suited to scalable floating storage and regasification solutions, enabling quick and economical implementation of mid-scale LNG import terminals.

The SSRC Containment System

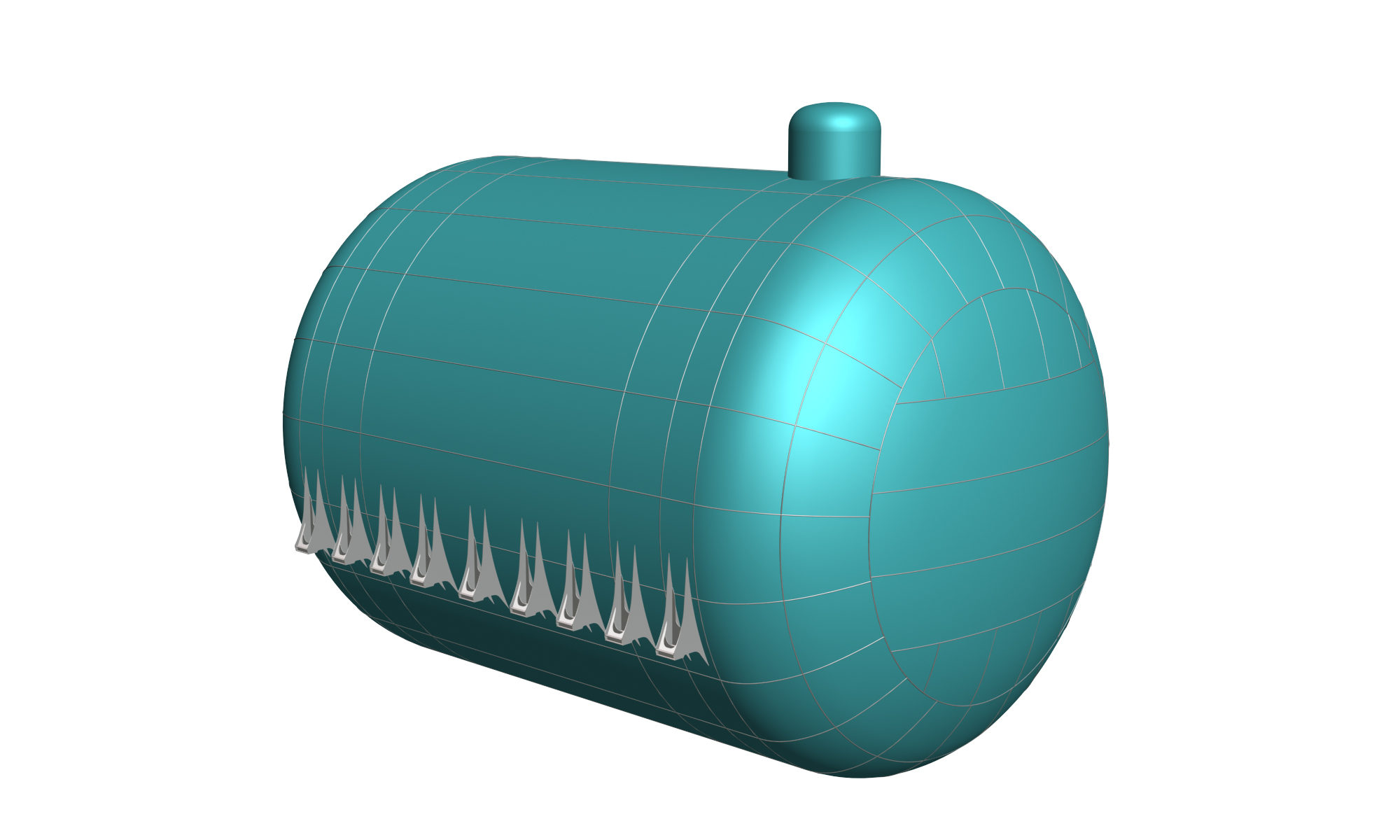

The Side Supported Reinforced Containment (SSRC) technology is a unique, patented Type B containment system designed to first principles for the safe carriage of all types of liquefied gases.

Multiple ring frames and external supports permit single tank capacities of up to 15,000 m3. The unique arrangement of the support bearings effectively decouples hull and tank deflections while distributing the tanks loads evenly throughout the cargo hold. The supports are situated near the hull neutral axis where deflections are minimal and torsional stiffness is greatest. Anti-floatation devices are integrated into each support.

Due to its simple geometry and use of repeated elements, the SSRC is uniquely suited to serial production and semi-automated fabrication methods.

Applications

The SSRC containment system is capable of transporting all types of liquefied gases including LPG, NH3, ethane, ethylene and LNG. It is suitable for liquefied gas carriers from 12,000 m3 to 45,000 m3.

As a floating storage solution, the SSRC system offers rapid deployment and modular expansion to capacities of 50,000 m3.

See examples of SSRC designs here.

Benefits for Owners and Operators

· Best mid-scale thermal performance

· Low boil-off rates

· Smaller cooling plant with lower operating costs

· Low cool-down costs

· Higher deadweight capacity

· Less expensive than equivalent Type A, C or membrane systems

Benefits for Fabricators and Shipyards

· Up to 50% lower material weight compared to Type A or C

· Single tank design and scantlings for all tanks

· Single fabrication setup for all tanks

· Series production of ring frames and supports

· Lower mechanical forming compared to Type C

· Up to 40% fewer welded parts compared to Type A

· Lower insulation cost for comparable thermal performance

Our Vision

“Our vision is the transformation of the mid-scale liquefied gas market through technical innovation and expert services, lowering costs for the existing LPG and Petchem markets and increasing the economic viability of emerging ethane, ethylene and LNG markets.

Our goal is to drive the growth of mid-scale gas projects by providing economical solutions for gas carriers and floating storage units.”

Our Business Model

We license our technology to qualified fabricators and shipyards and provide turnkey engineering services. The expertise, knowhow and experience at SSRC Technologies can support all aspects of your project from concept to delivery.

Read more