SSRC Technologies is pleased to present the following concept designs by leading gas carrier designer HB Hunte Engineering.

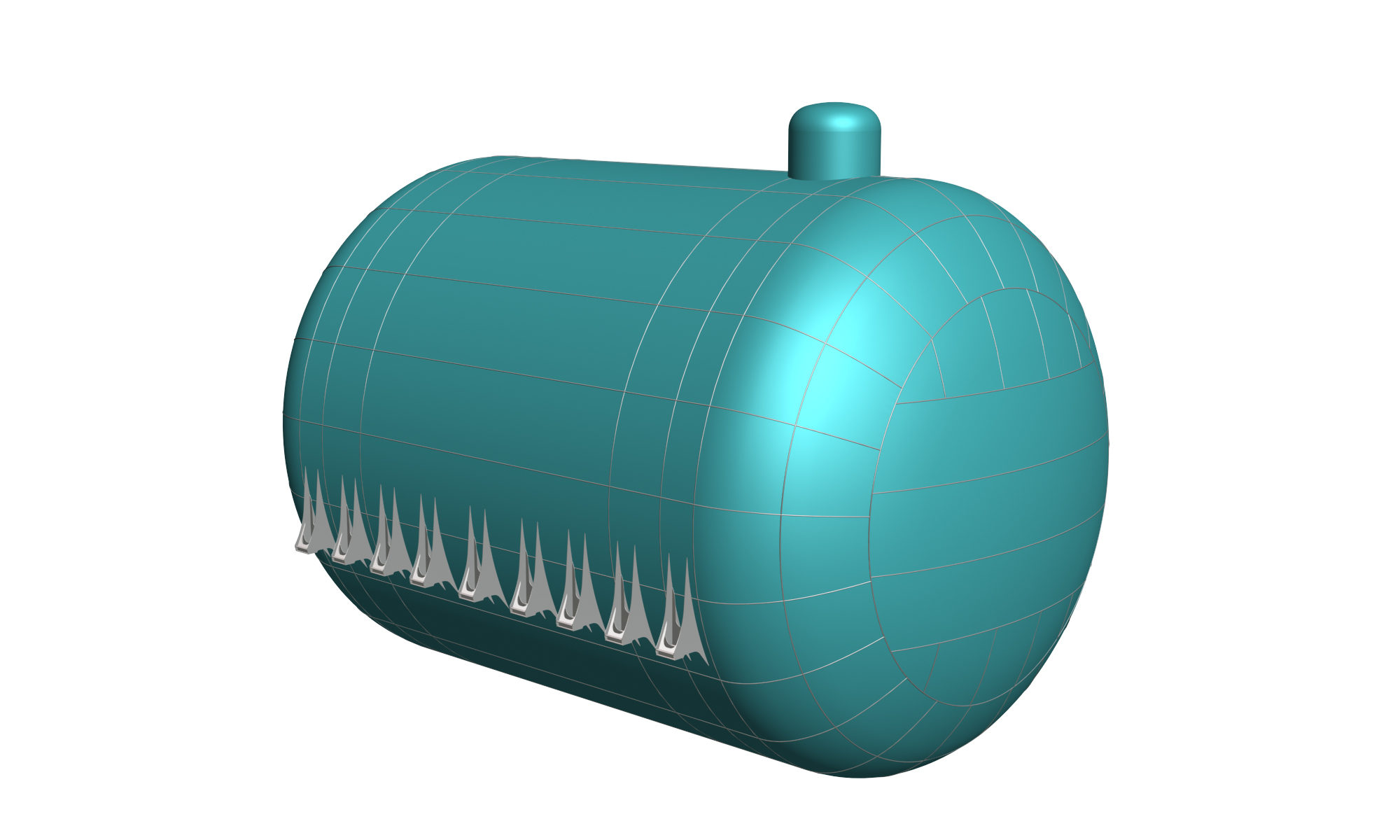

Due to the large diameter to length ratio and unique SSRC support system, designing an SSRC carrier requires careful consideration already in the parametric design phase.

Please contact us to find out how the SSRC system can benefit your next carrier or storage project.

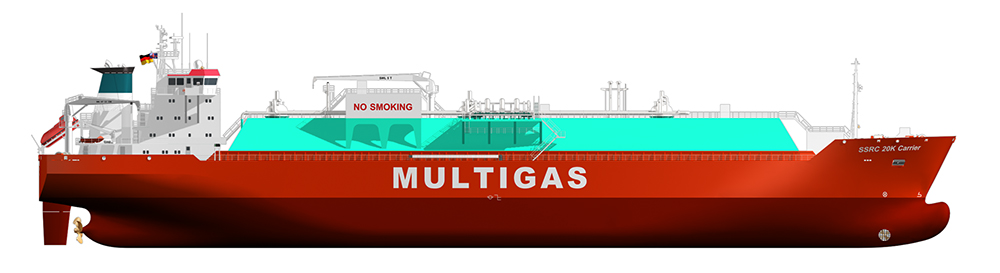

20,000 m3 Multigas Carrier

LPG, petchem and LNG all-in-one

The HB Hunte three tank 20K Multigas Carrier offers 20% more cargo capacity than the same length 17,000m3 bilobe Type C petchem carrier. It can transport LPG, ethylene and other petchems. Additionally, it can be configured for LNG. A truly flexible design, ready for the emerging mid-scale LNG market. The SSRC containment system has the best thermal performance of any mid-scale containment system and can reduce material weight by up to 50% compared to conventional Type A or C tanks. With a single design for all tanks, the costs of fabrication can be reduced by up to 30%.

Particulars

| LOA | 155.6 m |

| LBP | 147.4 m |

| Beam | 24.2 m |

| Depth | 14.8 m |

| Design Draft | 7.6 m |

| Speed | 16 kn |

| Consumption | 32 tpd on LNG |

| Range | 12,000 nm |

| Cargo Volume | 19,980 m3 |

| Deadweight | 12,700 tons |

| Propulsion | Dual Fuel option |

| Main Engine | 6G45ME C9.5 III |

| MCR | abt. 7,000 kW |

| Drive | Direct FP |

| Aux. Power | 6L23/30 H |

| Auxiliaries | 3 x 850 kWe |

| Cargo Tanks | 3 x 6,660 m3 |

| Design Pressure | 700 mbar g |

| Design Temp. | – 1630 C |

| Max. Density | 580 kg/m3 |

| BOG Rate | 0.16% per day |

| Discharge Rate | 2,000 m3/h |

| Pumps | 6 x Svanehoj |

| PSA Plant | 1 x 750 Nm3/h |

40,000 m3 LNG Carrier

The four tank 40,000 m3 LNG carrier is a compact design with the best mid-scale thermal performance of any other containment system. It has a higher allowable vapor pressure than Type A systems and can be offered as an ethane or ethylene carrier.

Particulars

| LOA | 199.8 m |

| LBP | 189,6 m |

| Beam | 29.4 m |

| Depth | 16.6 m |

| Design Draft | 8.3 m |

| Speed | 17.5 knots |

| Consumption | 32 tpd on LNG |

| Range | 12,000 nm |

| Cargo Volume | 40,700 m3 |

| Deadweight | 20,360 tons |

| Propulsion | Dual Fuel |

| Main Engine | DF Slow Speed |

| MCR | 10,300 kW |

| Drive | Direct FP |

| Aux. Power | 8L28/32H |

| Auxiliaries | 3 x 1680 kWe |

| Cargo Tanks | 4 x 10,300 m3 |

| Design Pressure | Type B/0.7 barg |

| Design Temp. | – 1630 C |

| Max. Density | 480 kg/m3 |

| BOG Rate | 0.16% per day |

| Discharge Rate | 4,000 m3/h |

| Reliq. Plant | 3 x 15 tpd |

| IGG | CO2 |

12,500 m3 FSU/FSRU

The single tank 12,500 m3 FSU/FSRU can be rapidly deployed to enable quick realization of green field terminal projects. Floating storage has been shown to significantly reduce permitting time and cost compared to shore-based storage projects. The units can be moored together in a number of configurations permitting capacities up to 50,000 m3.

Particulars

| LOA | 58.0 m |

| Beam | 28.6 m |

| Depth | 9.6 m |

| Design Draft | 5.8 m |

| Deadweight | 6,500 dwt |

| Cargo Tanks | 1 x 12,500 m3 |

| Design Pressure | 700 mbar g |

| Design Temp. | – 1630 C |

| Max. Density | 500 kg/m3 |

| BOG Rate | 0.15% per day |

| Transfer Rate | 1,500 m3/h |

| Regas Rate | 120 mmSCFD |

| Four Unit Configuration | |

| Capacity | 50,000 m3 |

| Footprint | 120 x 60 |